REFERENCE

REFERENCE

AI·Big Data

AI·Big Data

Based on over 20 years of experience in building smart factories,

DL Information Technology Co. Ltd. is creating manufacturing big data analysis

and AI application cases in various industrial fields

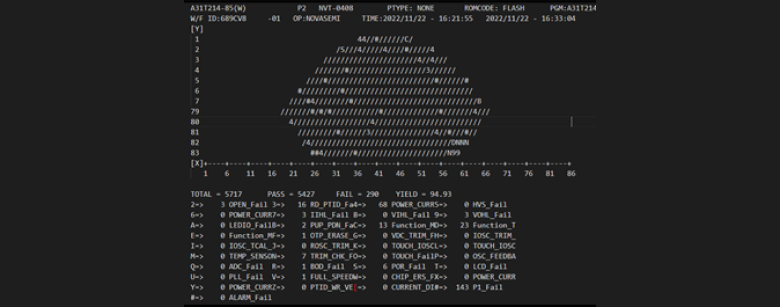

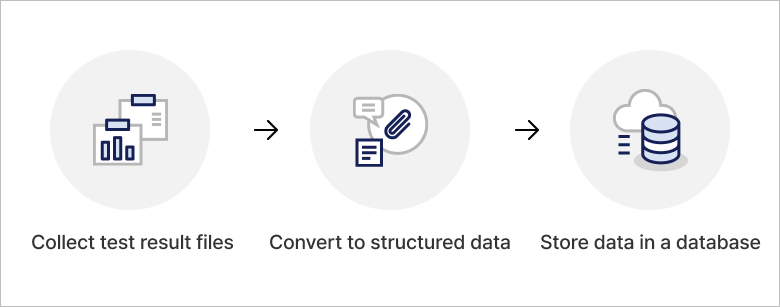

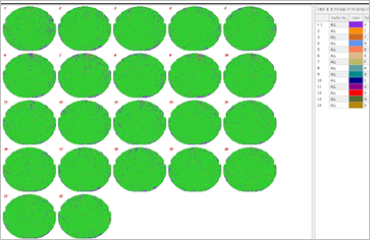

In order to improve wafer test result analysis efficiency, DL Information Technology Co., Ltd. provides data inquiry analysis processing and wafer chip defect prediction to semiconductor post-processing companies

AutoEncoder model structure

Defect status for each wafer chip

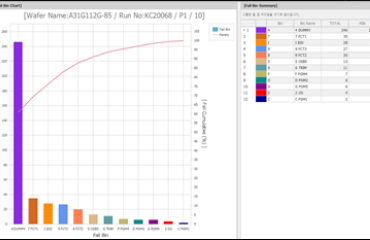

Fail Bin Chart

Difficult to manage

and analyze data

High probability

of errors

Data inaccuracy

Lower reliability

of results